Metallurgical microscopes are used in metallographic facilities to assess microstructure.

The company has capabilities for gauging and a Rockwell Hardness tester for testing mechanical and physical qualities.

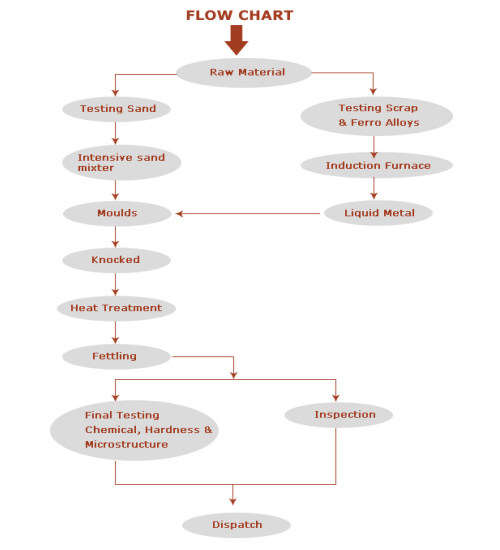

Liquid and foundry sand the quality of castings is significantly influenced by metal temperature. We offer all the tools needed to test and verify the qualities of molding sand. We have a microprocessor-based digital immersion pyrometer to guarantee the temperature of liquid metal. To guarantee reliable and consistent test results, all testing equipment is routinely calibrated by reputable and qualified organizations.

For elements like carbon, sulfur, chromium, manganese, phosphorus, silicon, nickel, molybdenum, etc., we have comprehensive wet chemical analysis procedures.

For breaking cylinders and grinding media, we have a ball breaking machine.

From a hygienic perspective, we have adequate drainage facilities and water borewell supply systems. We provide our employees with the necessary safety gear. We have a first aid station. In our factory, we have enough space to create dies, mold boxes, and pattern shops.